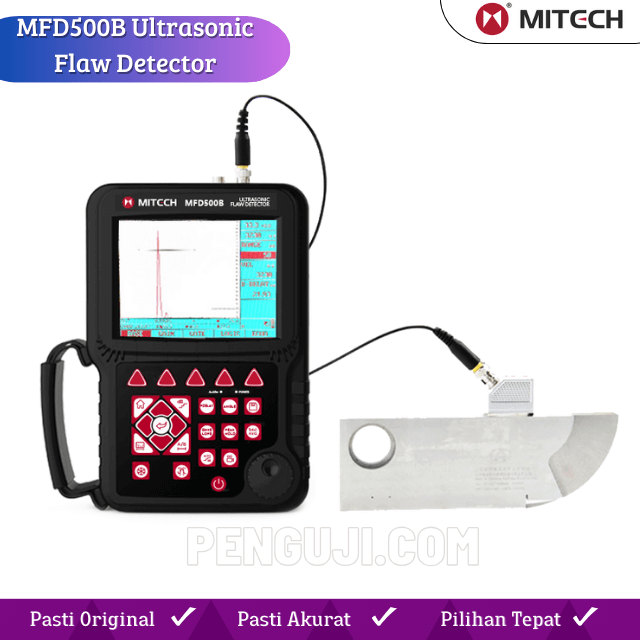

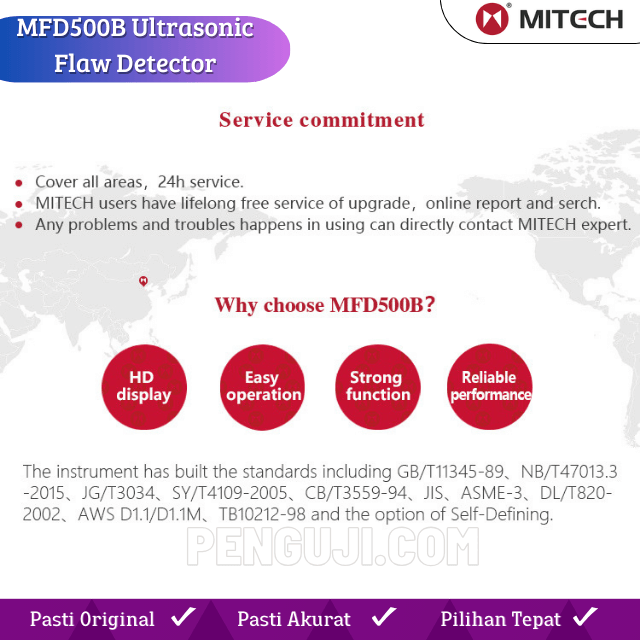

MFD500B Ultrasonic Flaw Detector MITECH menggunakan layar TFT LCD 320*240, dapat menguji, mengarahkan, mengevaluasi, dan mendiagnosis berbagai cacat seperti retak, cacat dalam, pori-pori, dan sebagainya di dalam benda kerja dengan cepat dan akurat tanpa merusak. Alat ini dapat digunakan di laboratorium maupun di lapangan rekayasa. Dengan rentang 0-9999mm, alat ini dapat memenuhi kebutuhan pemeriksaan cacat umum dalam industri manufaktur, industri metalurgi, industri pengolahan logam, industri kimia, dan sebagainya. Desain daya rendah dengan modul baterai lithium berkapasitas besar dan kinerja tinggi, alat ini dapat berdiam diri dalam waktu berbulan-bulan. Kualitas tinggi dengan harga terjangkau, ini adalah pilihan pertama untuk model ekonomis praktis alat uji ultrasonik.

Fungsi & Aplikasi Alat ini dapat digunakan secara luas untuk menemukan dan menentukan lokasi retakan tersembunyi, pori-pori, penyusunan ulang, dan ketidakselarasan serupa pada lasan, benda kerja tempaan, blok, sumbu, tangkai, tangki, bejana tekanan, turbin, dan komponen struktural.

Prinsip Kerja Ketika ada cacat dalam benda kerja dengan material homogen, karena cacat, ia akan memberi tahu antarmuka antara berbagai medium antara cacat dan benda kerja. Karena hambatan akustik berbeda di antarmuka, setelah gelombang ultrasonik berdenyut bertemu dengan antarmuka, itu akan memantulkan. Energi yang dipantulkan akan diterima oleh probe. Kemudian akan menunjukkan bentuk gelombang pantulan pada posisi absis tertentu di layar tampilan yang merupakan kedalaman cacat dalam benda kerja. Tinggi dan bentuk gelombang pantulan akan berbeda disebabkan oleh cacat yang berbeda yang mencerminkan karakter cacat itu sendiri.

Kondisi Kerja Suhu Operasional: -10℃ hingga 50℃; Suhu Penyimpanan: -30℃ hingga 50℃

Kelembaban Relatif: (20 ~ 95)% RH

Lingkungan sekitar harus dihindari dari getaran, medan magnet yang kuat, medium yang korosif, dan debu berat.

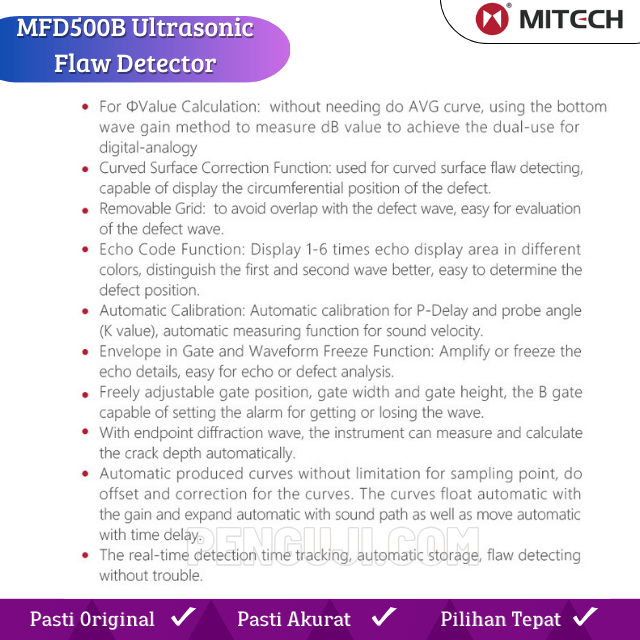

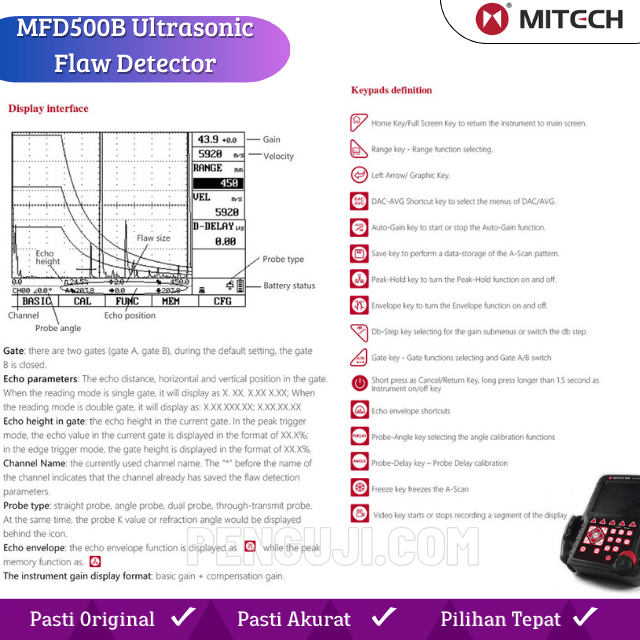

Fitur Instrumen Pemberitahuan Pintu Posisi pintu, lebar pintu, dan tinggi pintu dapat diatur sesuai keinginan. Pintu B dapat dipilih untuk mengatur pemberitahuan mendapatkan gelombang atau kehilangan gelombang. Beep di pintu dan lampu LED dapat memberi peringatan atau dimatikan (pemberitahuan lampu LED sangat efektif dalam lingkungan berisik).

Penyimpanan Data

Instrumen ini dibangun dengan penyimpanan massal, data dan file tidak akan hilang karena pemadaman daya instrumen. Konten penyimpanan meliputi parameter saluran, gambar gelombang, dan file video. Ini mendukung 100 kelompok parameter pemeriksaan cacat. Ini dapat diatur dengan baik untuk parameter kombinasi berbagai jenis probe dan instrumen serta menetapkan standar pengujian untuk setiap industri dengan bebas. Ini dapat menyimpan 10.000 gambar sinyal gema yang terdeteksi dan parameter. Ini dapat diakses, dibaca, dan mentransfer data melalui port USB.

Fungsi Video

Instrumen ini mendukung penyimpanan proses pemeriksaan sebagai file video dan menyimpannya ke kartu penyimpanan internal. File video dapat diputar ulang melalui instrumen. Instrumen ini dapat mendukung video selama 2 menit.

JAM REAL-TIME

Rekam dan simpan catatan pelacakan tanggal dan waktu deteksi secara real-time.

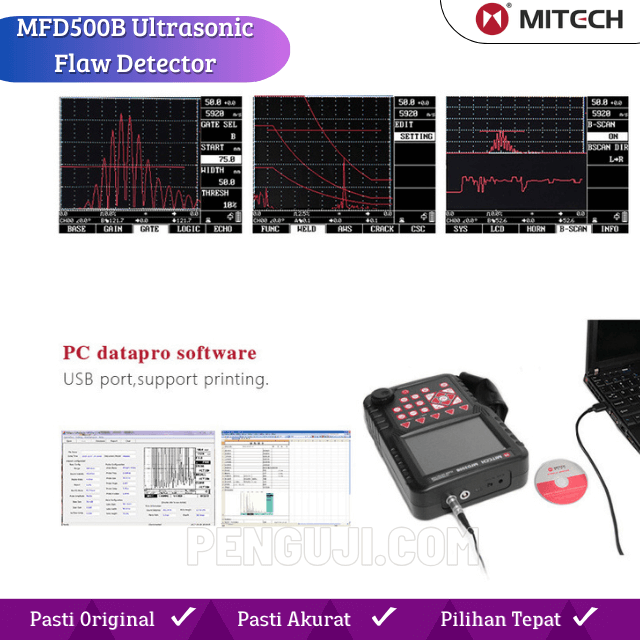

Komunikasi

Dengan antarmuka komunikasi USB2.0 berkecepatan tinggi, ini juga dapat menggunakan perangkat lunak khusus untuk mengunggah dan mengunduh data melalui port USB.

Modul Baterai

Modul baterai lithium berkapasitas besar mudah dipasang dan dilepas. Ini dapat diisi secara independen atau diisi dengan memasukkan kabel. Waktunya bekerja terus-menerus lebih dari 10 jam.

Cara Pengoperasian dan Perhatian Cara Operasi Sederhana:

- Hubungkan probe ke instrumen dengan kabel probe

- Nyalakan instrumen

- Pilih saluran dan bersihkan saluran yang ada

- Kalibrasi probe

Probe Lurus: P-Delay

Probe Sudut: P-Delay, Nilai-X, Sudut

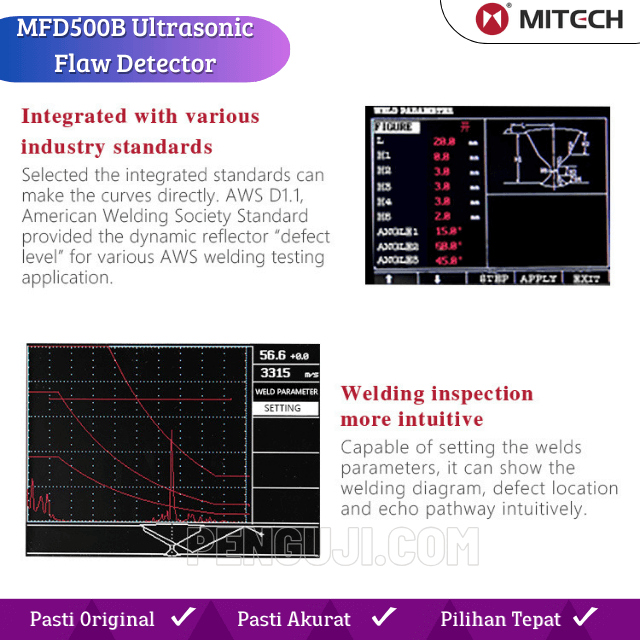

- Buat kurva AVG (probe lurus), kurva DAC (probe sudut)

- Pilih pengaturan fungsi

- Deteksi cacat dalam benda kerja

- Catat cacat

- Matikan instrumen setelah selesai

Opsional Produk

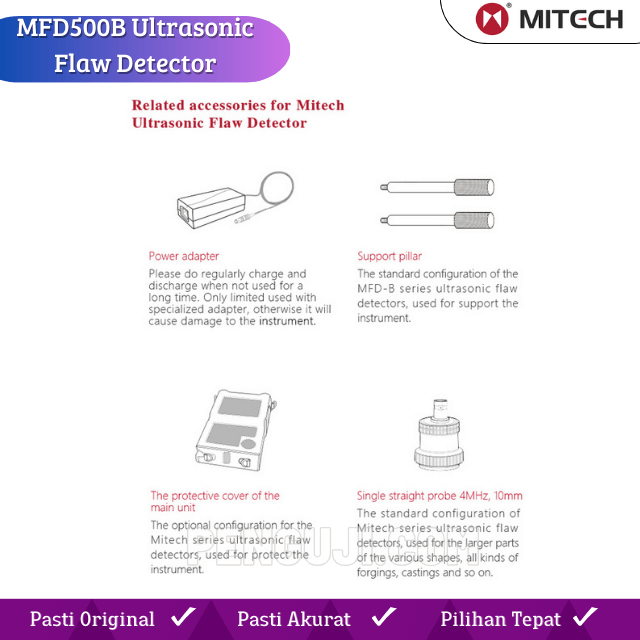

B Series Power Adapter

B Series Power Adapter of Mitech Ultrasonic flaw detector, the standard configuration of B series products with 9V voltage and 4A current, It is used for instrument charging. During charging, it will produce the constant voltage which can effectively protect the instrument, easy to use, safe and reliable. This instrument is only limited to the use of our company’s special battery pack and power adapter (charger), otherwise it may cause damage to the instrument.

Straight Probe

Mitech standard Straight Probe with the parameters of 4MHz, 10mm is the standard configuration of Mitech series ultrasonic flaw detectors. It is mainly composed of the piezoelectric crystal, damping block and protective film. The ultrasonic wave is emitted from the piezoelectric crystal, through the protective film and couplant enter into the measured workpiece. So for the straight probe, the actual distance of ultrasonic transmission is equal to the workpiece thickness plus protective film and couplant. So the straight probe should be calibrated before using to remove the distance between the protective film and the couplant to reduce the error caused by them and improve the measurement accuracy. The Straight Beam Probe is suitable for flaw detecting of larger parts with various shapes like forgings, castings and so on.

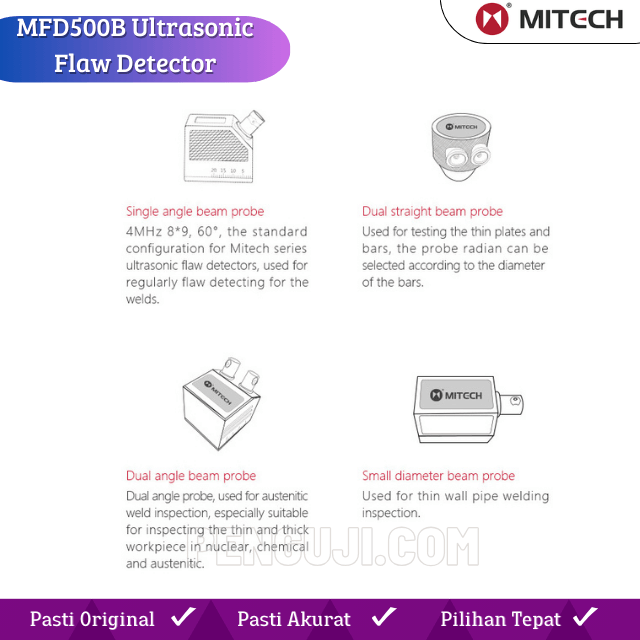

Angle Probe

Mitech standard Ultrasonic flaw detector Angle Probe with the parameters of 4MHz 8*9, 60°is the standard configuration. It is mainly composed of the piezoelectric crystal, damping block and wedge. The ultrasonic wave emitted from the crystal, through the wedge, it is converted to the transverse wave, and then incident to the measured workpiece. The wedge is made of organic glass, which can realize the waveform transformation. In order to avoid errors in calculating the defect distance, before using the angle probe, we need to calibrate its P-delay, angle and forefront. Through calibration, this part of the error can be automatically subtracted, thus improving the measurement accuracy .The Angle Beam Probe is suitable for normal flaw detecting like welds.

Single Probe Cable

The single cable for Mitech ultrasonic flaw detector, with standard length of about 20cmm, BNC/LEMO-LEMO00 probe cable is the standard configuration of the instrument, used for connecting the main unit with the probe.

Battery Module MB-02

Mitech B series products of Ultrasonic flaw detector have internal rechargeable Li-ion battery pack rated 7.2V at 8800 mAh,is the standard configuration.When using ,don’t disassemble ,and only for supplied charger ,otherwise ,the battery will be damaged .If it’s not used for a long time, be sure to regularly charge and discharge(about once a month), so as to avoid failure.

Power Cable

Power Cable of Mitech Ultrasonic flaw detector with length about 140cm, it is used for the connection between the main unit and power adapter. There are GB standard power cable, European standard power cable, British standard power cable, the United States power cable for selection.

Support Pillar

The B seris support pillar, the standard configuration for MFD B series products, with length of 9.5cm, it’s used to support the instrument.

Data processing software

Data Pro Software, the standard configuration of Mitech ultrasonic flaw detector, which has the functions of data management, graphic display, parameter setting, report printing, file management and so on. It is suitable for storing and managing the non-destructive flaw detecting report. With the analysis results provided by the software, it can make enterprise quality control more scientific basis and higher traceability. Improving the quality of enterprise information management level is the effectively guarantee for enterprise analysis the product qualification rate and improve the quality monitor. The software can also be used as effective tools in scientific research units related with metal materials, manufacturing plants, universities and other departments engaged in theoretical teaching, experimental analysis and basic scientific research

USB Communication Cable

The USB Communication Cable of Mitech Ultrasonic flaw detector, with length about 150cm, it is used for connecting the instrument with PC to realize the application of communicating with PC, analyzing and storing the data as well as printing the inspection reports.

Attached files

The Mitechs Ultrasonic flaw detector with customized packing documents has included product certificate, warranty card, product manual and packing list. The packing documents had used the special printed paper. The manual is with graphic design, beautiful, easy to understand, easy to save for a long time.

Reviews

There are no reviews yet.